With the continuous development of the industrial age, electrical connections have become an indispensable part of industrial life. To ensure the reliability of electrical connections, safe and reliable connections are a crucial foundation for stable system operation.

Electrical connectors are key components for achieving safe and reliable connections; however, due to the wide variety of types available, choosing the correct type is paramount. This article will serve as a comprehensive guide to help you understand and select the appropriate connector.

What are electrical connectors?

Electrical connectors are devices used to join electrical circuits, enabling the flow of electrical current between two or more components.

Electrical connectors are essential for establishing electrical connections in equipment and systems, providing reliable power transmission and signal integrity. Connectors were designed to ensure safe and secure connections in your circuits. The advent of connectors has made connecting, disconnecting, or repairing industrial electrical systems much easier and faster, eliminating the significant inefficiencies caused by tangled wiring.

Here are some factors to consider when choosing a suitable connector:

1. Current and voltage ratings

2. Conductor size (wire gauge, such as AWG)

3. Wiring method (screw, spring, solder, crimp, mating)

4. Protection rating (IP rating)

5. Material and plating

Types of Electrical Connectors

Classification by wiring method

| Types | Principle | Advantage | Shortcoming | Common Applications |

| Screw Terminal Connectors | Secure the wire with screw pressure | Strong connection, reusable, and suitable for various wire diameters. | Installation is slow and there is a risk of loosening. | Distribution boxes, industrial control cabinets, household circuit breakers |

| Spring Terminal Connectors | Using the constant force of a spring plate to clamp the wire | Quick wiring, maintenance-free, vibration resistant | The requirements for cable manufacturing are usually higher. | Lighting systems, building automation, modular equipment |

| Crimped Terminal Connectors | Use a special tool to press the terminal metal sleeve firmly onto the wire. | High reliability, excellent consistency, suitable for mass production | Special crimping tools are required; it is usually a one-time connection. | Automotive wiring harnesses, aerospace, high-vibration environments |

| Plug-in connectors | The male-female plug-in structure facilitates quick connection/disconnection. | Modular design, easy to maintain and replace | Additional locking mechanism may be required. | Interconnection between sensors, actuators, mobile devices, and circuit boards |

Classification by shape and function

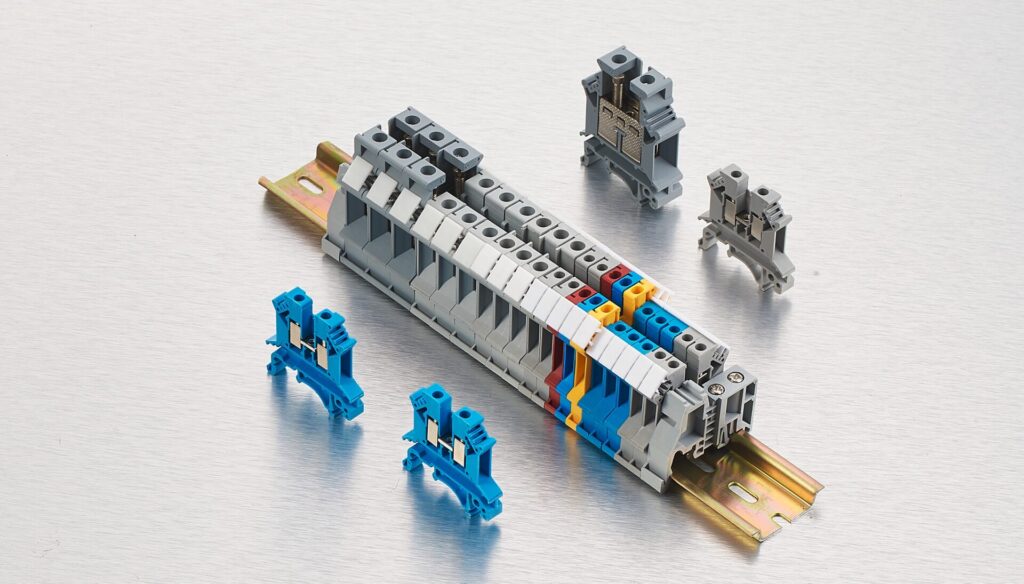

1.Din Rail terminals:Modular terminals that can be snapped onto standard DIN rails for PCB wiring and power distribution.

2.Barrier terminals:Screw terminals with plastic partitions prevent short circuits between multiple circuits.

3.High-current terminals:Junction boxes that can be used with high current.

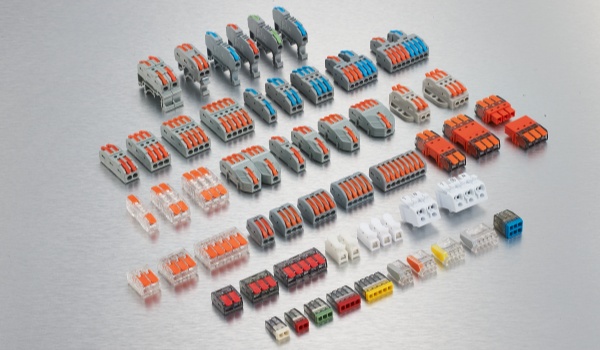

4.Quick-connect terminals:Wiring methods include direct plug-in and lever-type, requiring no professional skills and are quick and easy to use.