Transparent lever wire connectors are highly popular and practical wire connectors in modern electrical installations, particularly for home renovations and lighting circuit connections. Their transparent casing design and lever-operated mechanism are their most distinctive features.

What is the Transparent lever wire connector?

Transparent lever wire connectors, also known as “lever-type terminal blocks” or “twist-free connectors,” are electrical accessories designed for quick and secure wire connections.

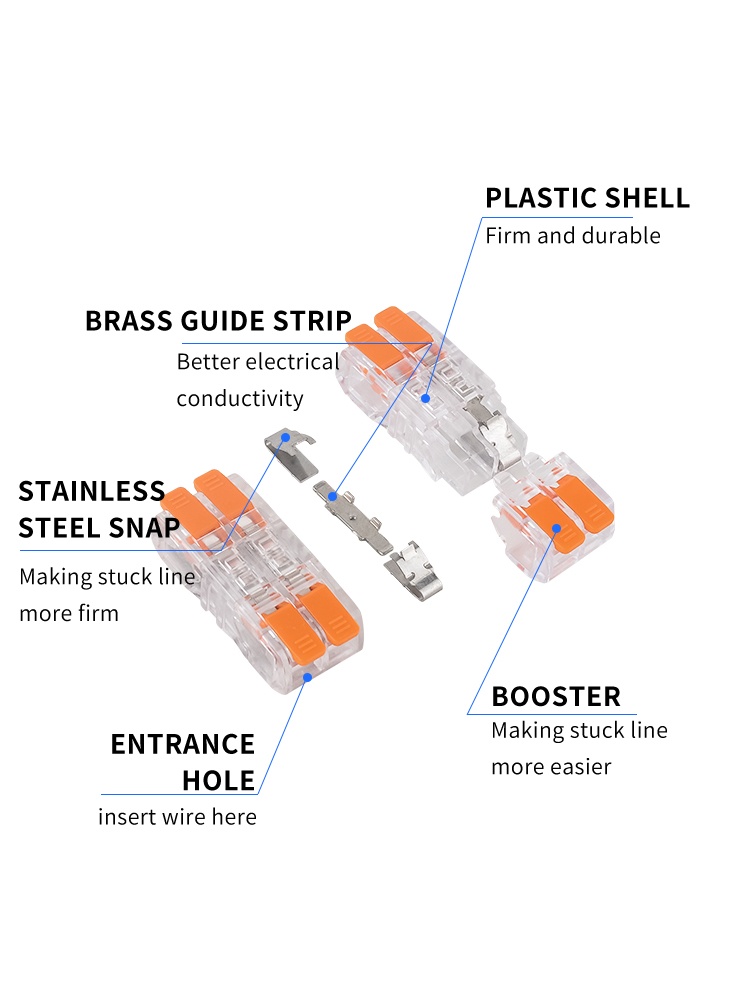

It consists of several parts:

- Transparent housing: Constructed from flame-retardant PC (polycarbonate) material. The transparent design allows users to directly observe internal wire connections and verify proper positioning of the wire cores.

- Operating lever: Each terminal hole corresponds to a small lever that can be flipped.

- Metal Reed: The internal core conductive component, made of tin-plated copper, offering excellent conductivity and rust resistance. When the lever is pressed down, it compresses the reed, thereby clamping the wire.

Core Working Principle of Transparent Lever Wire Connectors

Its operation is extremely simple: just lift the lever, insert the wire, and press down the lever to complete the connection.

- To engage the lever: Use your finger to flip the lever corresponding to the hole into the vertical (open) position. At this point, the internal metal spring plate opens, preparing for wire insertion.

- Inserting the wire: Insert the bare copper wire, with its insulation stripped to an appropriate length (typically 10-12mm), into the open wire hole.

- Press the lever: Return the lever to the horizontal (closed) position. During this process, the lever drives the internal mechanical structure, forcing the metal spring contacts to clamp tightly onto the wire, forming a secure and low-resistance electrical connection.

Key point: Neither connection nor disconnection requires any twisting of the wires, achieving true “twist-free” operation.