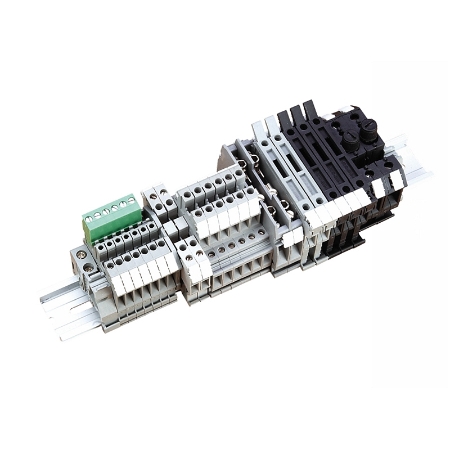

DIN Rail Terminal Blocks is a modular electronic component designed to connect and distribute wires in a safe and organized manner. It can be mounted on a standardized metal rail, the DIN rail.

You can think of it as the industrial equivalent of a “terminal block” or “outlet strip”, but it’s more specialized, safer, and stronger.

It can also be understood as the electrical control cabinet “traffic hub”, where all wires converge, transfer and distribution, so that the cabinet wiring has become incredibly clear and standardized.

The advantages of DIN Rail Terminal Blocks are their modular and standardized design. You can combine the terminal blocks with different functions like a Lego puzzle and mount them on a uniform rail according to your needs.

Main components of DIN Rail Terminal Blocks

-

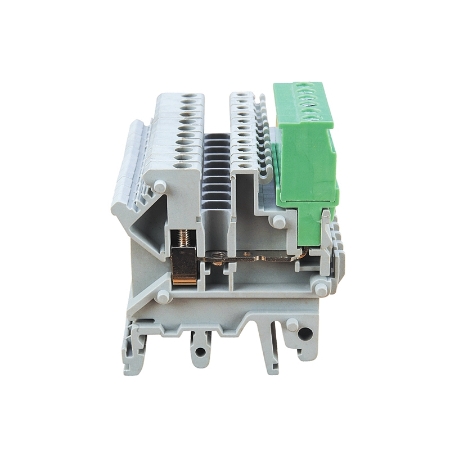

Insulated housings

Made of high strength engineering plastic PA66, it has good insulation, flame retardant and corrosion resistance.

-

Conductor

The internal conductor is made of copper alloy with a tin-plated surface to ensure excellent electrical conductivity and resistance to oxidation.

-

Clamping Mechanism

- Screw Clamp:The most traditional and common way, it uses screws to tighten to secure the wires.

- Spring Clamp:Utilizes spring tension to clamp wires for faster wiring and better vibration resistance.

- IDC:No need to strip the wire, directly piercing the wire insulation to realize the connection, mainly used for communication and signal lines.

-

Clip at the bottom for securely fastening the terminal block to the DIN rail, easy to install and remove

-

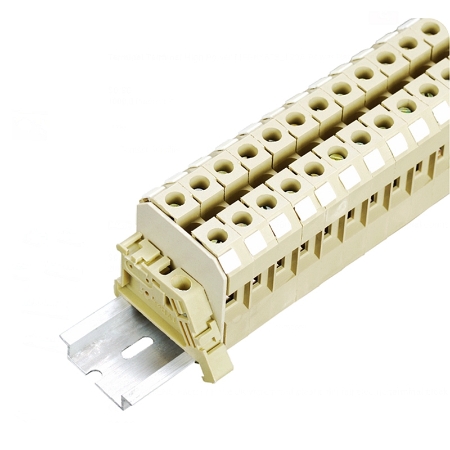

Marking System

Each terminal block is provided with a labeling area or label paper for numbering or indicating the function, which facilitates installation, commissioning and post maintenance.

Why we use the DIN Rail Terminal Blocks?

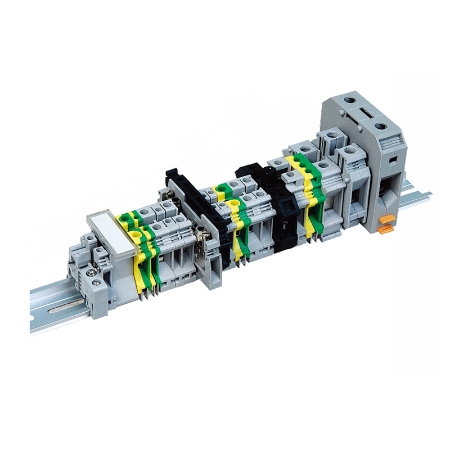

- Makes messy wire connections neat and standardized, making post maintenance easier.

- The modular design makes the best use of space and enables high-density installation to save space.

- Compared to traditional point-to-point wiring, the standardization and compatibility of DIN Rail Terminal Blocks greatly reduces wiring time and effort, especially in complex systems.

- DIN Rail Terminal Blocks are protected against accidental electric shocks and short circuits due to the insulation of the housing, and the specialized internal clamping mechanism ensures that the connection is secure and will not loosen, especially in vibrating environments. When testing or replacing wiring, the terminal blocks can be easily disconnected or connected without having to move the entire wiring harness. Clear labeling greatly simplifies troubleshooting.

- Because of the modular design of DIN Rail Terminal Blocks, it is possible to freely combine different numbers and types of terminal blocks (e.g. power, ground, signal, fuse types, etc.) according to circuit requirements.