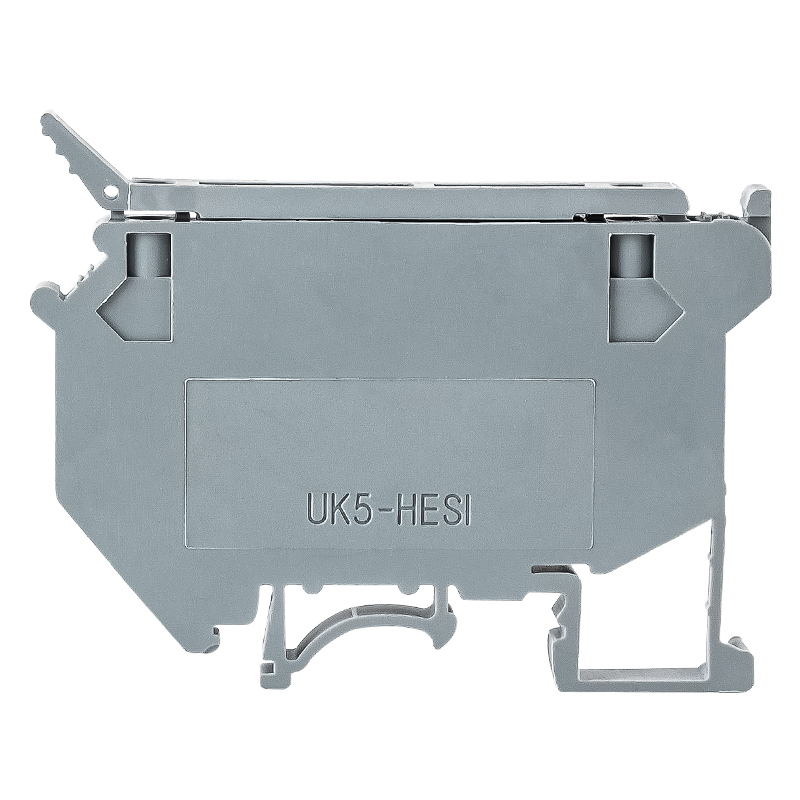

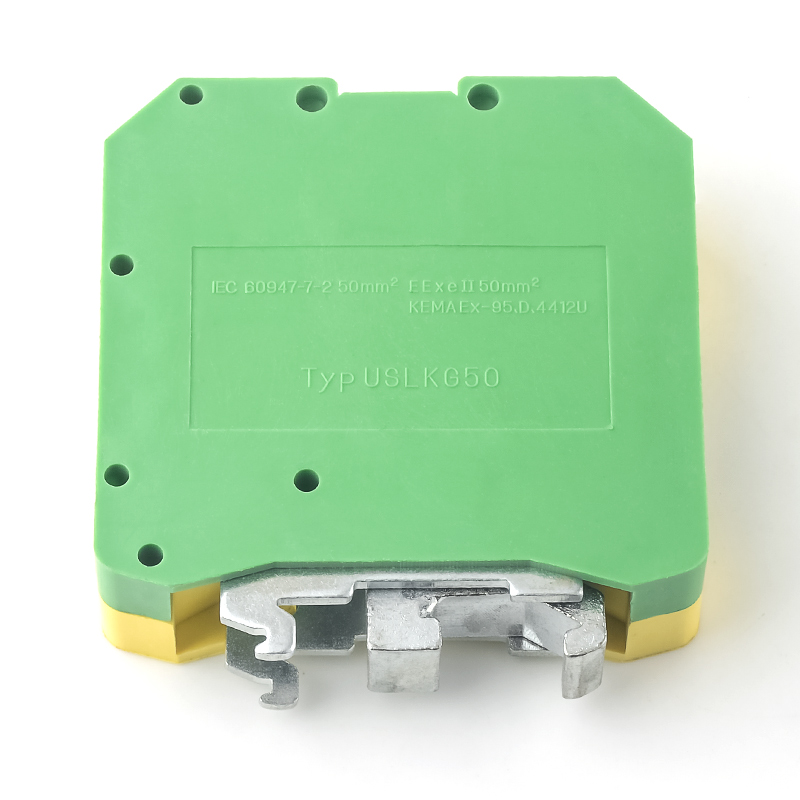

UK Terminal Blocks with Exceptionally High Utilization Rate

JINH UK Terminal Blocks widely used in industrial automation and control cabinets where modular wiring is required. Their dual- or triple-layer design maximizes space utilization, making them ideal for installations with limited mounting space. The product design complies with standards such as IEC 60947-1 and GB 14048.

Quick QuoteJINH UK Din Rail Terminal Block

Explore the features and benefits of JINH UK Terminal Blocks to discover how our UK terminal blocks meet your wiring needs.

- 1.Housing Material:PA66,Flame Retardant Rating UL94 V0

- 2.Conductive materials:Tin-plated copper,Resistant to corrosion and oxidation, extending service life

- 3.Internal Structure:Screw-driven Rectangular Crimping Frame,Will not loosen due to high-frequency vibration, preventing power outages and overheating risks.

- 4.Ensures mechanical compatibility between different brands

- 5.High-quality terminal blocks mean fewer failures and less downtime.

- 6.Low-resistance, high-reliability electrical connections

UK Terminal Block Wiring Video

Send Inquiry NowHow the JINH UK DIN Rail Terminal Blocks Function

The JINH UK DIN Rail Terminal Block operates by applying downward pressure through the rotational motion of screws, pushing the clamping frame downward to firmly press the wire against the conductor strip below. Current flows from the wire through the clamping frame, across the conductor strip, and then to the clamping frame and wire on the opposite side.

Send Inquiry Now

High Efficiency of JINH UK DIN Rail Terminal Block

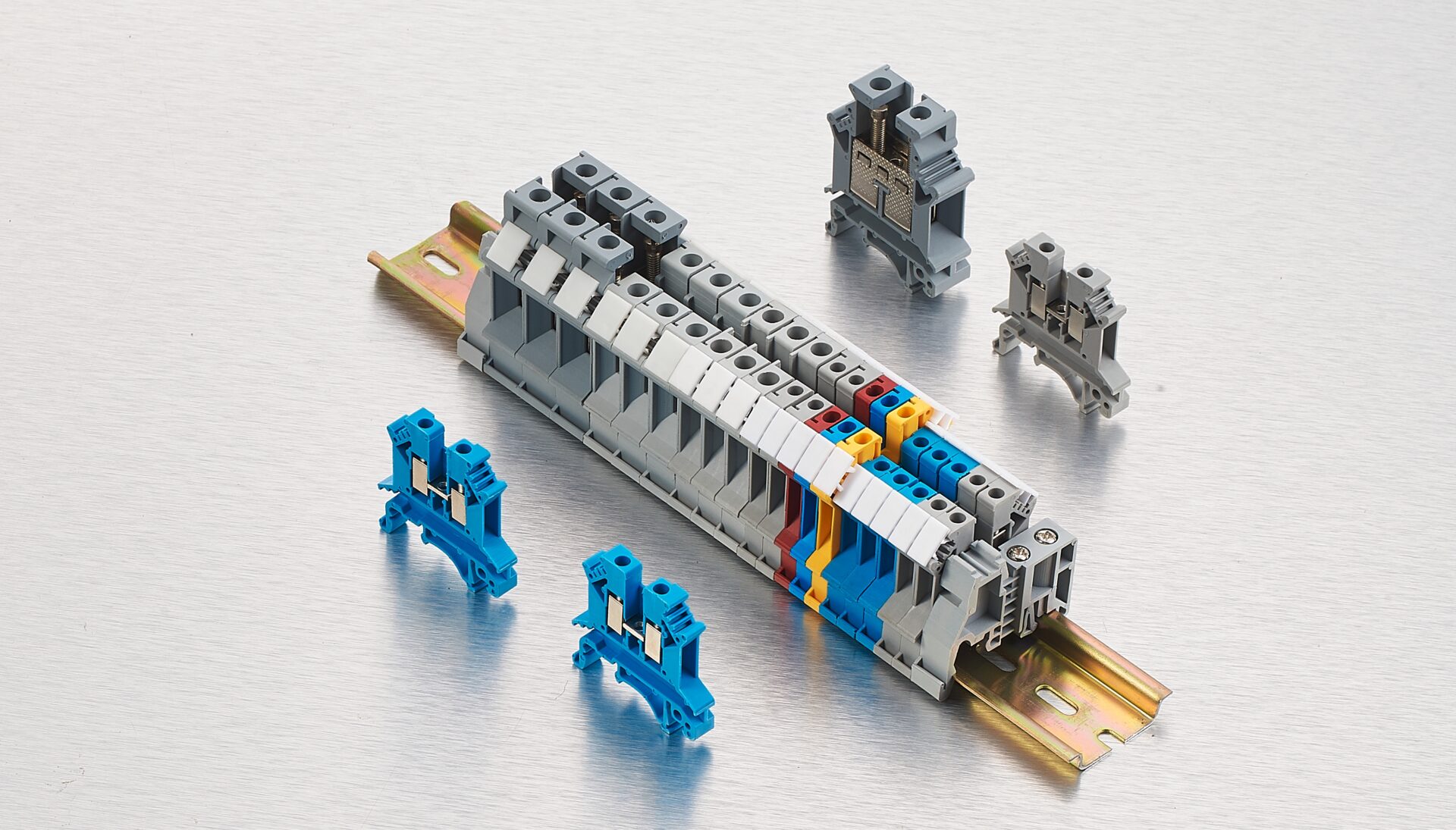

JINH remains committed to serving users with high-quality products. The JINH UK DIN Rail Terminal Block,with its modular design, maximizes space utilization and makes wiring more convenient and effortless. Compared to traditional wiring methods (such as wire twisting or tape splicing), the wiring approach of JINH UK DIN Rail Terminal Block offers significantly higher installation efficiency.

Application Scenario

Industrial Automation

Control cabinet

Mechanical Equipment Manufacturing

Electricity and Energy Industry

Building Automation

Transportation and Communications Infrastructure

Benefits of using UK terminal blocks

Space-saving

Modular design saves space.

Stability

The internal structure remains stable and will not loosen due to high-frequency vibrations, thereby preventing power outages and overheating risks.

Compatibility

Almost all major electrical equipment manufacturers produce products to this standard and JINH UK Series DIN Rail Terminal Blocks ensure mechanical compatibility between different brands.

A wide range of accessories to assist

JINH UK Series DIN Rail Terminal Blocks can be equipped with accessories such as fixing parts, partitions, connecting strips, marking strips, etc., further enhancing safety and facilitating post-installation maintenance.

Reduce maintenance costs

Although the procurement cost of individual terminals for the JINH UK Series DIN Rail Terminal Blocks may be higher than that of some inexpensive terminals or traditional wiring methods, the overall cost is significantly lower.

Resource

UK Terminal Block FAQ

The rated current of the terminal block is ≥ the maximum expected current of the circuit. The wire gauge you are using is within the compatible range indicated for the terminal block.

Screw Terminal Wiring: When using multi-strand twisted wires, it is strongly recommended to use wire lugs to prevent wire spreading, poor connection, and damage to the wire core when tightening the screw. For single-core wires, this is not necessary.Spring Terminal Wiring: Most modern spring terminals are designed to accept multi-strand or single-core wires that have been precisely stripped (typically 11mm) without the need for wire lugs. However, the use of wire lugs is also entirely acceptable.

Facilitates installation and maintenance, saving time for fault diagnosis.

• It is a safety requirement to prevent misoperation on energized equipment.

• Enhances professionalism, serving as a hallmark of high-quality electrical installations.

Absolutely not. Standard terminal blocks are designed solely for internal use in distribution boxes and are not dust or water resistant. When used in outdoor, humid, or dusty environments, terminal blocks with corresponding protection ratings must be selected, such as IP65, IP66, or IP67. These terminal blocks are equipped with gaskets and sealant, which can effectively prevent the ingress of moisture and dust.

We are a manufacturer and have specialized in terminal blocks for 20 years.

Yes,we can provide free samples if the quantity is not too much but delivery fee needs to be paid.